10 valuable tips to use your furler properly

Not a boat show goes by without a visit of one or more cruisers with a furler problem (all brands combined). These few tips should therefore answer many questions.

A natural suspect often cleared

The statement of the problem is “I have a problem with my furler”, but in reality, the furler is not always the source of the problem… and rarely! This reminds me of the very relevant quote from the sales manager of an international large sailmaker: “It’s not all about providing the most beautiful sail in the world, you also need to provide a good anti-torsion, a good furler and the tips for use that go with it.”

The components:

So let’s start by recalling the components of the system:

- The sail

- The anti-torsion line or cable

- The furler (drum for the lower part and swivel for the upper part)

To which I add to be more precise:

- The drum and swivel attachment system (snap shackle, shackle, lashing eye, 3:1 …)

- The drum and swivel fittings (halyard, padeye, chain-plate …)

- The furling line

- The user manual or instructions for use.

- The weather conditions and the point of sailing of your sailboat.

As in any good police investigation, each element must be considered suspicious, but common sense requires me to treat repeat offenders as a priority.

Repeat offenders:

Although the furler is rarely incriminated, make sure before starting your investigation that the drum and swivel rotate by hand without excessive effort.

Let us now focus on the much touted repeat offenders. In theory, each rotation of the drum (operated by the furling line) would simultaneously rotate the swivel. This should be the case if we used a long metal bar instead of the anti-torsion line. In practice, we often see the drum doing 2 or 3 rotations (and even more) before driving the swivel (fixed on the head of the sail).

This brings us to a first set of tips:

1- Read this article!

And read it to the end. Don’t let its apparent length stop you. It is a quick and great read.

2- The drum must be securely attached to the boat.

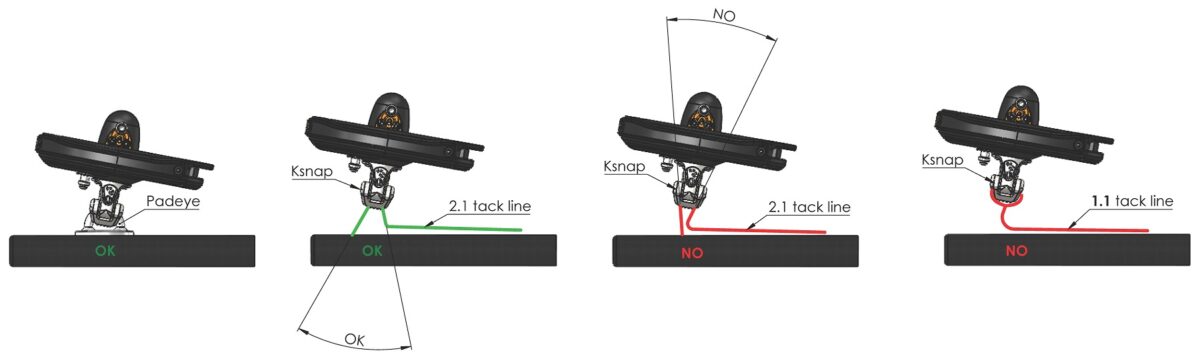

The most frequent case is to see a furler fixed on a simple rope that allows to bring the furler on the bowsprit. This is a frequent case to be avoided. It is mandatory to have a system that prevents the drum from turning on itself. Only the continuous line wheel must rotate and especially not the continuous line wheel protection system (casing).

If you have to install a furler on a bowsprit without having to do a balancing act, the only solution is the use of a 2 or 3-strand purchase (2:1 or 3:1). Do not use single rope (1:1).

3- The system must be powered on.

If you do not put enough tension in the halyard, the anti-torsion will twist on itself. Feel free to add tension for the furling and unfurling phases. Sailboats from 45 to 50 feet and beyond are often equipped with 2:1 halyards. The interest is to be able to multiply the tension by 2 with the same effort. The downside is that it takes twice as long to hoist the sail and you end up with a nice plate of noodles on the deck once the sail is in position.

4- The luff must be at the right length.

It seems obvious, but it is more common than we think. If the luff of the sail is too long, the swivel will come up against the halyard exit and it will be impossible to add more tension. Make sure the swivel is at a good distance from the mast and is not obstructed by another halyard.

5- The anti-torsion must be of good quality.

The anti-torsion is the rope that connects the drum and the swivel. It is installed in the luff of the sail for Code 0 or staysails. It is outside for the use of asymmetric spinnaker.

Poor quality anti-torsion is clearly the 2nd cause of malfunction. If you have to make more than 3 or 4 drum rotations before moving the swivel, the problem is the anti-torsion.

In addition, most furler manufacturers offer thimbles that are perfectly adapted to their products, but they are not installed by sail lofts. The thimble is the aluminium or stainless steel part through which passes the anti-torsion cable that attaches to the furler. The use of these thimbles is a guarantee of sustainability. As much as possible, avoid basic stainless steel teardrop thimbles that will very quickly damage your furler.

Each thimble is designed to accept a maximum diameter of anti-torsion. My advice: Ask your sailmaker not to hesitate to use the largest diameter possible, especially if it is a Code 0, a staysail or an asymmetric spinnaker. The maximum diameter is often specified on the technical documentation.

For sailboats over 50 feet and for luffs over 20 m long, I recommend that you seriously consider using anti-torsion cables instead of anti-torsion lines. These are custom-made technical textile cables with much higher anti-torsion properties than conventional line. You will find a non-exhaustive list of brands in this article dedicated to anti-torsions.

It can sometimes be tempting to choose a slightly (or really) undersized furler. This also means that it will be impossible to install the correct anti-torsion diameter. In any case, always discuss the quality of anti-torsion with your sailmaker. He will be able to answer your questions and give you the best advice.

Last tip: The older your anti-torsion is, the more important it is to add tension.

6- Do not neglect the furling line.

The furling line or working furling line is a more important accessory than it seems.

- Use the diameter recommended by the manufacturer. Too large = too much friction. You’ll wear yourself out furling. Too small = high risk of slipping.

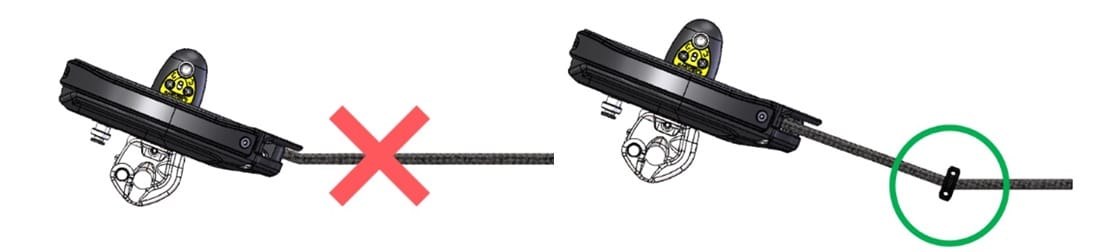

- Check the quality of the splice. Most of the furlers are equipped with continuous line wheels and are used with a continuous furling line. If the junction is not correctly made, this can create an extra thickness and get stuck in the furler.

- Align the furling line. This is a recommendation found in most manuals. Too many angles = too much effort. Do yourself a favor and use a few blocks or rings to align everything properly.

- Attach the end of the furling line. If you do not attach the other end of the furling line, you are greatly exposing yourself to the risk of a knot (a simple turn in the line) that will jam at the entrance of the furler. If this happens in a strong sail unfurling, you have a good chance of breaking your furler.

- Prefer a direct access. Avoid too many angles. If you can furl your sail when you are close to the furler, but it becomes “mission impossible” from the cockpit, it is a sign that there is too much friction on the furling line. Simplify the path or use real bearing blocks instead of friction rings.

- Watch out for twists. If the line twists on itself, especially in the return area, the forces will be very high and will give the impression that the whole system is blocked. This is a very common issue. Easy to solve.

- Choose a furler that holds the furling line well. This is a critical issue (corrected or not) for some brands. If the furling line can come out of the continuous line wheel through the space between the continuous line wheel and the protective casing, you should expect a complicated situation at some point… but never at the right time for sure.

7- Do not undersize your furler…

and follow as much as possible the recommendations of the manufacturers. I have already mentioned the problem of the anti-torsion dimension, but you can also add the potential problem of a too small drum diameter. The wider the continuous line wheel, the easier it will be to use (more torque). Several manufacturers now offer larger versions and this makes the difference once on board.

8- Tame your furler.

If you have ever used a spinnaker sock, you are now aware that there are certain rules to follow if you want to “choke” your spinnaker with elegance. No matter how sophisticated your furler and sail are, you need to find the best way to do it on your own.

A few leads though:

- For furlers equipped with a locking system (non-return), take the time to understand how it works.

- Test furling with different halyard tensions

- Test furling with different wind angles

- Test furling with different wind forces

- Test furling with different sheet angles (move the clew forward or back)

- Test furling with different sheet tensions

The configuration often chosen is a well-tensioned halyard, a slightly unvented sail and not too much tension in the sheet, but I assure you that you will not waste your time making several attempts.

9- Read the manuals.

You will be surprised to find a few good tips in there!

10- Exchange with professionals.

In the Internet-everywhere era, it is tempting to make your choice on your own. However, even with my excellent advice, I will never stop advising you to talk to people with experience.

Please also read: KarverPedia – The importance of anti-torsion line or cable

Article written byTanguy de Larminat. Tanguy is the managing director of Karver. He is also a specialist in cruising multihulls. He is a sailing instructor and professional skipper. He has several transatlantic to his credit and has managed Catana’s customer service (deliveries & after-sales service) for 4 years as well as a refit shipyard for 12 years in the south of France.

If you have any comment, please email him.

Translation : adGallica (carole@adgallica.fr)

Crédit : HH Catamarans (HH66)